Thin-walled parts in the form of cylinders, steps, cones, spheres,

boxes and other irregular shapes can be produced by the drawing

process. In combination with other press forming processes such as

flanging, bulging, flaring, and shrinking, it is also possible to

manufacture parts with extremely complicated shapes. Therefore, in

the production process of industrial sectors such as automobiles,

airplanes, tractors, electrical appliances, instruments,

electronics, etc., the deep drawing process occupies a very

important position.

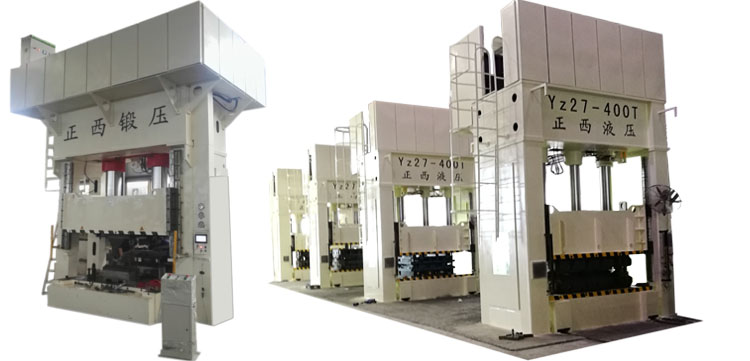

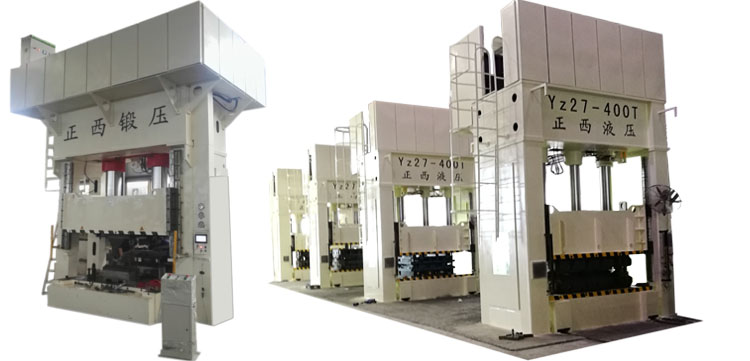

Yz27 Series Frame-type Hydraulic Press is a kind of multifunctional

precision machine which has high speed.

Optimized design, the frame is entirely welded with steel plates,

and treated to relive stress by tempering for high precision.

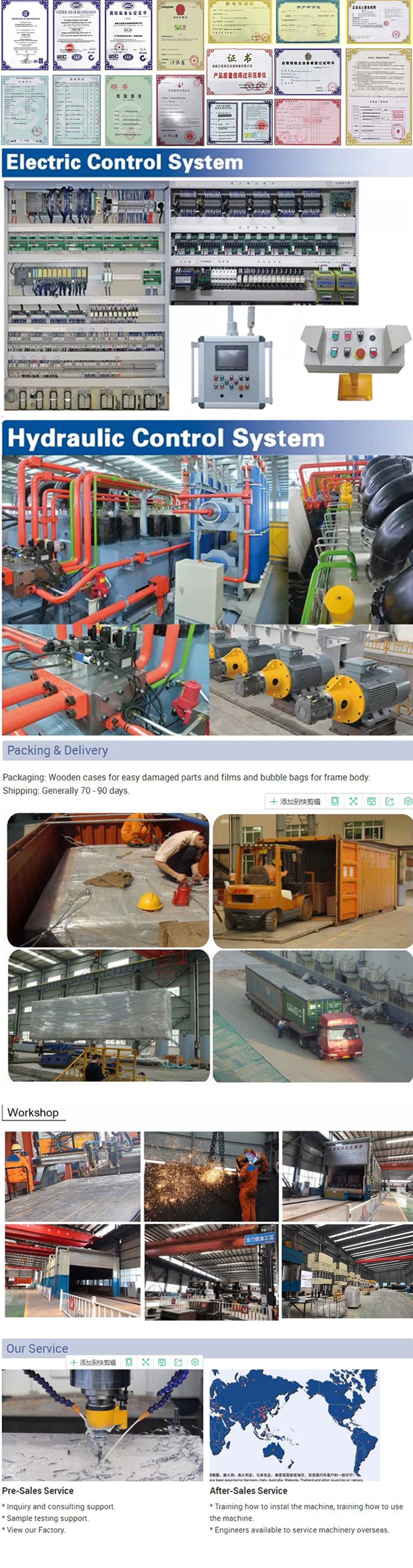

Cartridge valve equipped for hydraulic control system, reliable,

durable and less hydraulic shock, shorter connection pipeline and

fewer release points.

Centralized button control system, with adjustment, hand and

semi-auto operation modes at operator`s choice (set-stroke single

and set pressure single).

Four-angle and eight-side guide rail in high precision and with

strong capacity against deflection, concentrated lubrication.

New type of oil cylinder sealing components marked by high

reliability and long service life.

Sliding blocks operating in high speed, ensuring high efficiency.

The slide operating pressure, no-load quick travel and low-speed

movement can be adjusted according to technological requirements.

Hydraulic cushion is fitted beneath the worktable; adequate

knockout hole and hydraulic cushion are prepared on the plate of

worktable with the operating modes including drawing, ejection and

no ejection.

The working speed of this equipment is 3 to 4 times faster than

that of Y41. It employs eight-side guide device and ejecting

device, which can automatically eject workpieces with accurate

guiding and fast speed.

The drawing device can be added to this equipment in order to

change moulds easily. But the stretching of large metal parts needs

to add hydraulic cushion to this equipment.

Features

1.Hydraulic machine that used the hydrostatic pressure to process

metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming

process, such as: forging, stamping, cold extrusion, straightening,

bending, flanging, sheet metal deep drawing, powder metallurgy,

press-fit etc.

3.Significant technical and economic advantages in reducing weight,

reducing the number of parts and the number of molds, improve the

stiffness and strength, reduce production costs, etc.

Parameters

| Mold | unit | 63T | 100T | 160T | 200T | 250T | 315T | 500T | 630T | 800T | 1000T | 1250T |

| Main cylinder (slider) process specs | Max.press force | KN | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 30000 |

| Max.return force | KN | 150 | 100 | 315 | 450 | 540 | 630 | 1000 | 1000 | 1200 | 1600 | 2100 |

| Down speed | mm/s | 100 | 100 | 160 | 160 | 140 | 140 | 140 | 250 | 200 | 150 | 150 |

| Slow speed | mm/s | 20 | 15 | 15 | 15 | 12 | 15 | 15 | 15 | 15 | 15 | 12 |

| The proportion of floating pressing speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 |

| Press speed | mm/s | 10 | 10 | 10 | 10 | 7 | 8 | 8 | 8 | 8 | 8 | 6 |

| Return speed | mm/s | 120 | 120 | 120 | 110 | 95 | 100 | 100 | 150 | 150 | 120 | 120 |

| Max.stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 |

| Top cylinder process specs | Max.ejection force | KN | 280 | 440 | 450 | 900 | 900 | 1250 | 1800 | 2200 | 2200 | 2750 | 10000 |

| Max.pull force | KN | 280 | 360 | 450 | 750 | 750 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Eject speed | mm/s | 80 | 34 | 65 | 55 | 50 | 50 | 50 | 60 | 60 | 60 | 60 |

| Floating speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 |

| Return speed | mm/s | 80 | 42 | 95 | 70 | 70 | 50 | 50 | 60 | 60 | 60 | 60 |

| Upper center cylinder process specs | Max.press force | KN | 60 | 60 | 60 | 125 | 150 | 125 | 200 | 200 | 240 | 240 | 500 |

| Max.return force | KN | 30 | 30 | 30 | 76 | 76 | 76 | 130 | 130 | 140 | 140 | 200 |

| Max.stroke | mm | 30 | 30 | 30 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 |

| Under center cylinder process specs | Max.press force | KN | 70 | 70 | 125 | 160 | 160 | 200 | 200 | 300 | 300 | 300 | 1000 |

| Max.return force | KN | 40 | 40 | 75 | 100 | 100 | 100 | 100 | 200 | 200 | 200 | 260 |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Upper floating cylinder process | Max.press force | KN | 120 | 120 | 130 | 250 | 250 | 300 | 400 | 400 | 480 | 480 | 1000 |

| Max.return force | KN | 60 | 60 | 65 | 150 | 150 | 160 | 200 | 200 | 240 | 240 | 250 |

| Max.stroke | mm | 45 | 45 | 50 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 70 |

| Effective worktable size | L-R | mm | 580 | 720 | 780 | 1000 | 1000 | 1000 | 1200 | 1320 | 1400 | 1600 | 2400 |

| F-B | mm | 490 | 580 | 640 | 940 | 940 | 960 | 1140 | 1200 | 1200 | 1350 | 1460 |

| Max.pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.filling height | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Main motor power | KW | 7.5 | 11.5 | 18.5 | 22 | 22 | 30 | 48 | 67 | 82 | 100 | 100 |

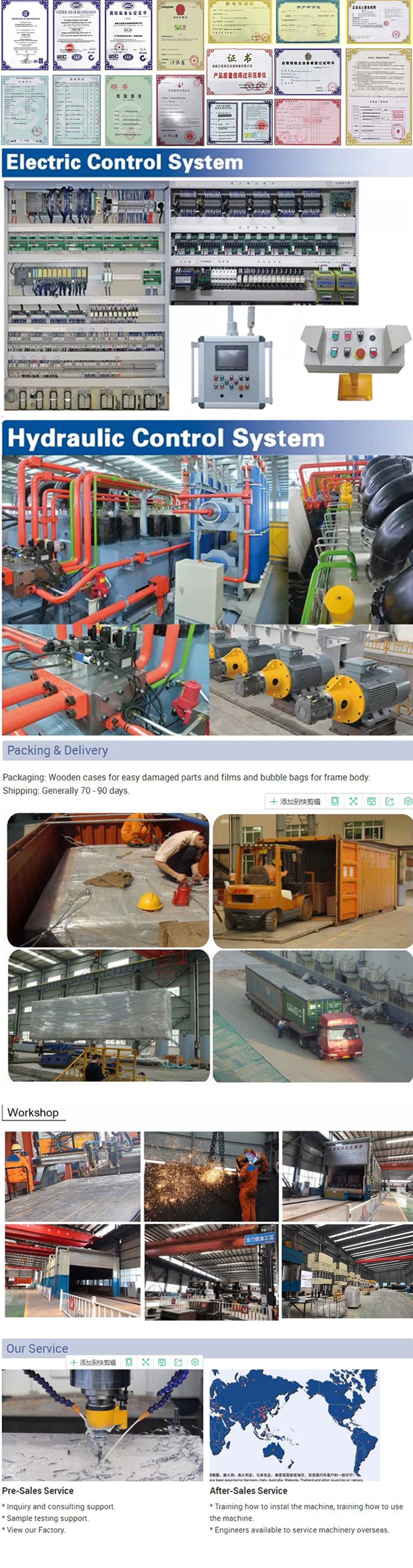

Packaging and delivery