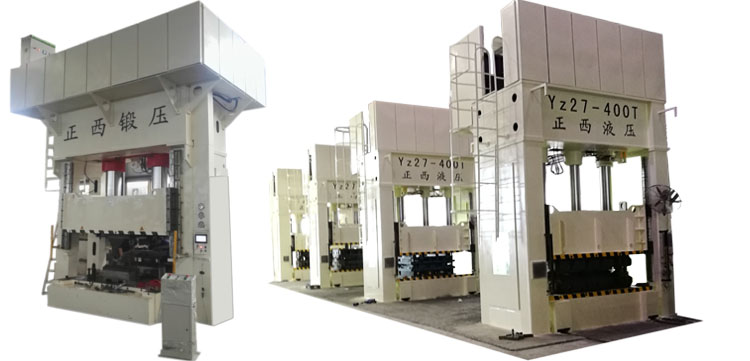

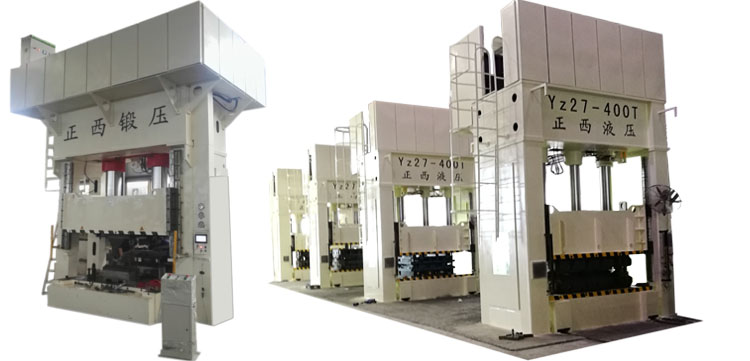

Hydraulic Deep Drawing Press Metal Stamping Press 1300Ton Automatic

hydraulic press Hydraulic metal press

This equipment is especially suitable for various processes such as

bending, forming and flanging of central load parts. It can also be

used for punching and blanking processing after being equipped with

punching buffer device. It is a ship industry, pressure vessel

industry, chemical industry, etc. Preferred product.

It is used for the process of stretch forming, tumbling, bending

and stamping of sheet metal parts. It can also be used in general

pressing process. It can add punching buffer, material feeding and

moving table according to user needs.

The slider is a steel plate welded box structure, and the bottom

plate of the slider is a single steel plate to ensure sufficient

rigidity and strength. The slider is guided by 45° guide rails, and

four guide plates are arranged on the left and right vertical

columns. The guide rails of the sliders are vertically moved on the

guide plates, and the movement guiding precision is adjusted by the

inclined iron on the slide rails to ensure the movement table. The

parallelism is easy to adjust, the adjustment precision is high,

the precision after adjustment is good, and the anti-offset

capability is strong. The side of the friction pair of the guide

rail is made of alloy material, and the other side is made of

copper-based alloy material. In addition, the guide plate is

quenched and has a hardness of more than HRC55, good wear

resistance and long service life. The slider rail surface is

provided with a refueling hole for refueling to lubricate the

moving part. Hydroforming Press

Precautions for frame hydraulic presses during city test:

Before starting the machine, you must understand the mechanical

principle of the machine, let the motor run 2-3 times. If the

inverter is reversed, adjust the two-phase power cord. After

replacing the hydraulic oil, the pressure of the relief valve

should be adjusted to a small value. After normal operation,

slightly increase the pressure, drain the air in the system and

test the pressure.

Features

1.Hydraulic machine that used the hydrostatic pressure to process

metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming

process, such as: forging, stamping, cold extrusion, straightening,

bending, flanging, sheet metal deep drawing, powder metallurgy,

press-fit etc.

3.Significant technical and economic advantages in reducing weight,

reducing the number of parts and the number of molds, improve the

stiffness and strength, reduce production costs, etc.

Parameters

| Mold | unit | 63T | 100T | 160T | 200T | 250T | 315T | 500T | 630T | 800T | 1000T | 1250T |

| Main cylinder (slider) process specs | Max.press force | KN | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 30000 |

| Max.return force | KN | 150 | 100 | 315 | 450 | 540 | 630 | 1000 | 1000 | 1200 | 1600 | 2100 |

| Down speed | mm/s | 100 | 100 | 160 | 160 | 140 | 140 | 140 | 250 | 200 | 150 | 150 |

| Slow speed | mm/s | 20 | 15 | 15 | 15 | 12 | 15 | 15 | 15 | 15 | 15 | 12 |

| The proportion of floating pressing speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 |

| Press speed | mm/s | 10 | 10 | 10 | 10 | 7 | 8 | 8 | 8 | 8 | 8 | 6 |

| Return speed | mm/s | 120 | 120 | 120 | 110 | 95 | 100 | 100 | 150 | 150 | 120 | 120 |

| Max.stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 |

| Top cylinder process specs | Max.ejection force | KN | 280 | 440 | 450 | 900 | 900 | 1250 | 1800 | 2200 | 2200 | 2750 | 10000 |

| Max.pull force | KN | 280 | 360 | 450 | 750 | 750 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Eject speed | mm/s | 80 | 34 | 65 | 55 | 50 | 50 | 50 | 60 | 60 | 60 | 60 |

| Floating speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 |

| Return speed | mm/s | 80 | 42 | 95 | 70 | 70 | 50 | 50 | 60 | 60 | 60 | 60 |

| Upper center cylinder process specs | Max.press force | KN | 60 | 60 | 60 | 125 | 150 | 125 | 200 | 200 | 240 | 240 | 500 |

| Max.return force | KN | 30 | 30 | 30 | 76 | 76 | 76 | 130 | 130 | 140 | 140 | 200 |

| Max.stroke | mm | 30 | 30 | 30 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 |

| Under center cylinder process specs | Max.press force | KN | 70 | 70 | 125 | 160 | 160 | 200 | 200 | 300 | 300 | 300 | 1000 |

| Max.return force | KN | 40 | 40 | 75 | 100 | 100 | 100 | 100 | 200 | 200 | 200 | 260 |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Upper floating cylinder process | Max.press force | KN | 120 | 120 | 130 | 250 | 250 | 300 | 400 | 400 | 480 | 480 | 1000 |

| Max.return force | KN | 60 | 60 | 65 | 150 | 150 | 160 | 200 | 200 | 240 | 240 | 250 |

| Max.stroke | mm | 45 | 45 | 50 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 70 |

| Effective worktable size | L-R | mm | 580 | 720 | 780 | 1000 | 1000 | 1000 | 1200 | 1320 | 1400 | 1600 | 2400 |

| F-B | mm | 490 | 580 | 640 | 940 | 940 | 960 | 1140 | 1200 | 1200 | 1350 | 1460 |

| Max.pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.filling height | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Main motor power | KW | 7.5 | 11.5 | 18.5 | 22 | 22 | 30 | 48 | 67 | 82 | 100 | 100 |