Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd.

Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. was founded in 2009 with a registered capital of 30 million yuan.

It is a company integrating research, design, manufacture and sales

of hydraulic equipment. The company is located in the "land of

abundance" "the hometown of panda" Chengdu. The factory covers an

area of about 75 acres. It has always been known for producing

high-precision, high-quality hydraulic presses, and has established

a good reputation and credit in the domestic and foreign

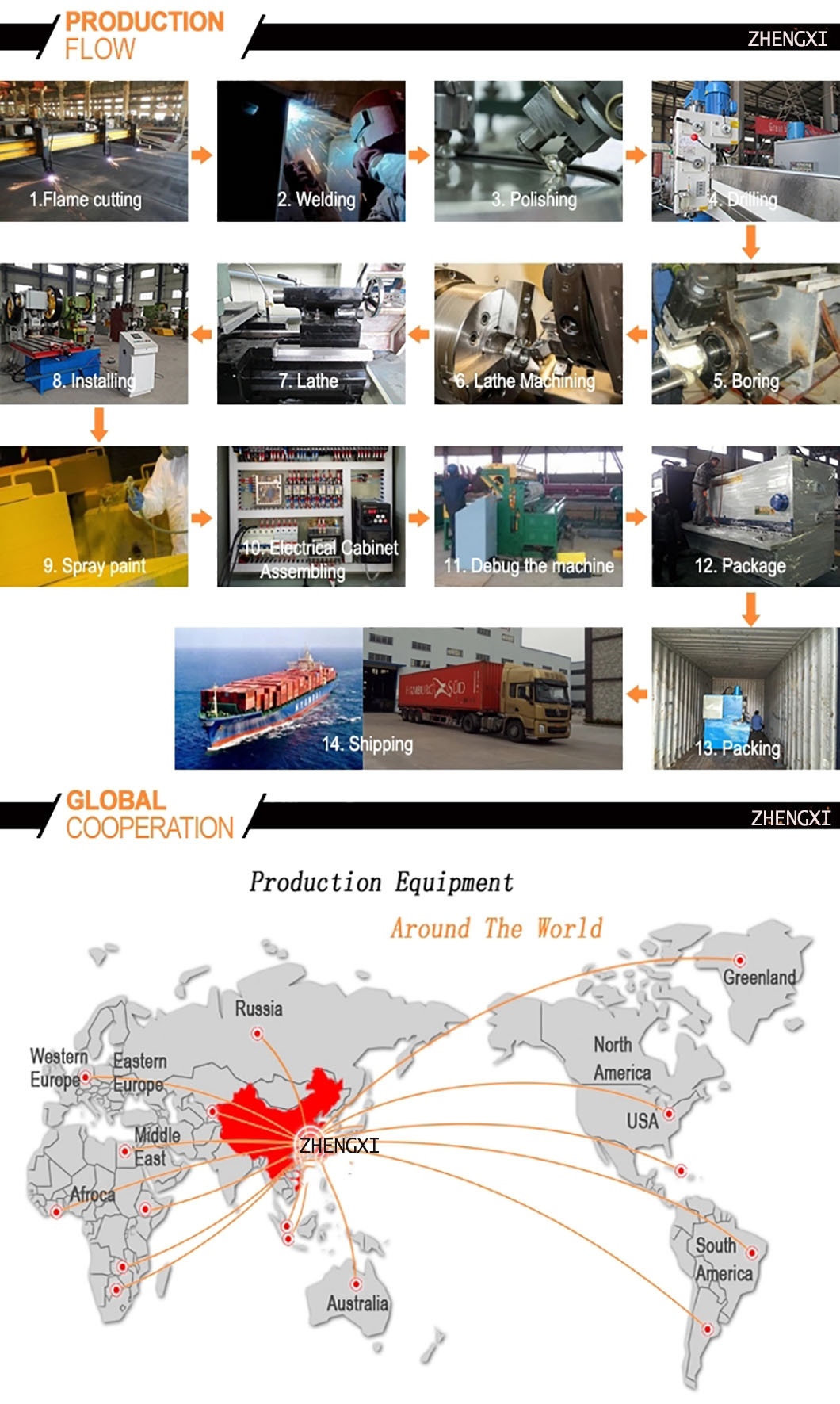

industries. The factory has more than 70 sets of finishing

equipment, including Japan's Mitsubishi floor-standing composite

boring machine, imported heavy-duty lathes, large vertical vehicles

and other processing equipment. Ultrasonic flaw detector, hardness

tester, spectrometer imported dynamic balance machine and other

testing equipment, to ensure that every process in the production

process is improved. The main product series include: 100-16000

tons of molding presses; 100-20000 tons of metal drawing (stamping)

forming hydraulic presses. Products are widely used in automotive,

aerospace, high-speed rail, shipbuilding, power, bathroom and other

industries, providing key equipment and advanced technical support

for a number of important industries.

ZHENGXI Hydraulic is an ISO, SGS and CE certified company. In the process of

development, we have been attaching great importance to developing

and cultivating talents. Thus, we enjoy a number of professional

and skilled talents who are committed to innovation and

improvement. We are proud of high manufacturing capacity, good

ability to design and develop, rich experience in quality control

management as well as high competitiveness and all time pursuit of

offering cost-effective and quality assured presses.

ZHENGXI Hydraulic has been conforming to the latest trend of technology development.

Sincere and credible attitude, flexible business strategy, high

quality products and perfect service are rendered to all our home

and abroad customers. We assure you a worthwhile cooperation with

us on your project. We sincerely looks forward to your visit and

guidance and long-terms cooperation with your esteemed company in

the near future.